Facilities, Capabilities, and Equipment at the Center for Detectors

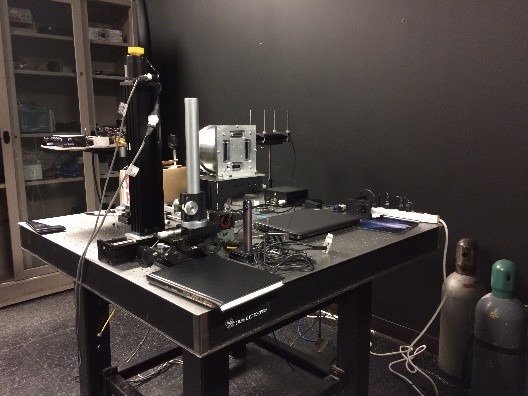

The Center for Detectors (CfD) is located in Engineering Hall (Building 17). The CfD headquarters consists of approximately 7,000 square feet of office and research laboratory space. CfD lab space includes the Rochester Imaging Detector Laboratory (RIDL), the Lobozzo Photonics and Optical Characterization Laboratory, the Integrated Photonics Laboratory, the Experimental Cosmology Laboratory, the Laboratory for Advanced Instrumentation Research (LAIR), the Quantum Imaging and Information Laboratory, the Suborbital Astrophysics Laboratory, and the Electrical and Optical Characterization Lab for LED devices.

Facilities within CfD include a permanent clean room, ESD stations, vacuum pumping systems, liquid and closed-cycle cryogenic dewars, optical benches, flow tables, light sources, UV-IR monochromators, thermal control systems, cryogenic motion control systems, single-photon detector systems, a cryogenic optoelectronic probe station, vibration testing stations, a suborbital rocket payload assembly area, power supplies, general lab electronics, and data reduction computers. In addition to these dedicated facilities, the CfD has access to facilities within the Semiconductor and Microsystems Fabrication Laboratory (SMFL) and other areas across the RIT campus.

Rochester Imaging Detector Lab (RIDL)

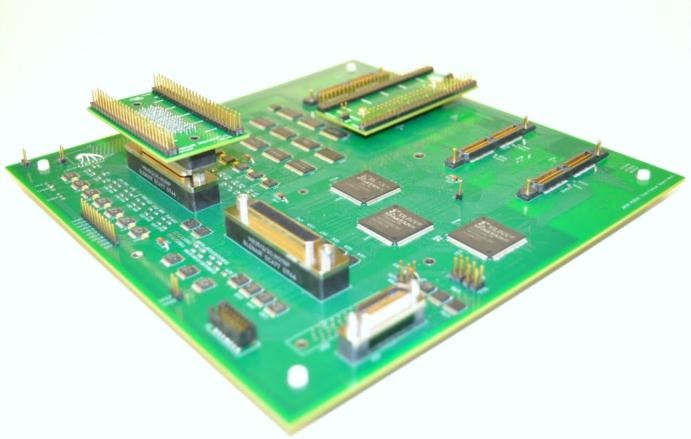

The RIDL detector testing systems use four cylindrical vacuum cryogenic dewars. Each individual system uses a cryocooler that has two cooling stages: one at ~60 K (10 W) and another at ~10 K (7 W). The cold temperatures yield lower detector dark current and read noise. The systems use Lakeshore temperature controllers to sense temperatures at 10 locations within the dewars and to control heaters in the detector thermal path. This thermal control system stabilizes the detector thermal block to 400 K RMS over timescales greater than 24 hours. The detector readout systems include two Astronomical Research Camera controllers with 32 digitizing channels, a 1 MHz readout speed, and 16-bit readout capability. The readout systems also contain one Teledyne SIDECAR ASICs with 36 channels and readout speeds up to 5 MHz at 12-bits and 500 kHz at 16-bits, custom FPGA systems based on Altera and Xilinx parts, and a JMClarke Engineering controller with 16 readout channels and 16-bit readout designed specifically for Raytheon Vision System detectors.

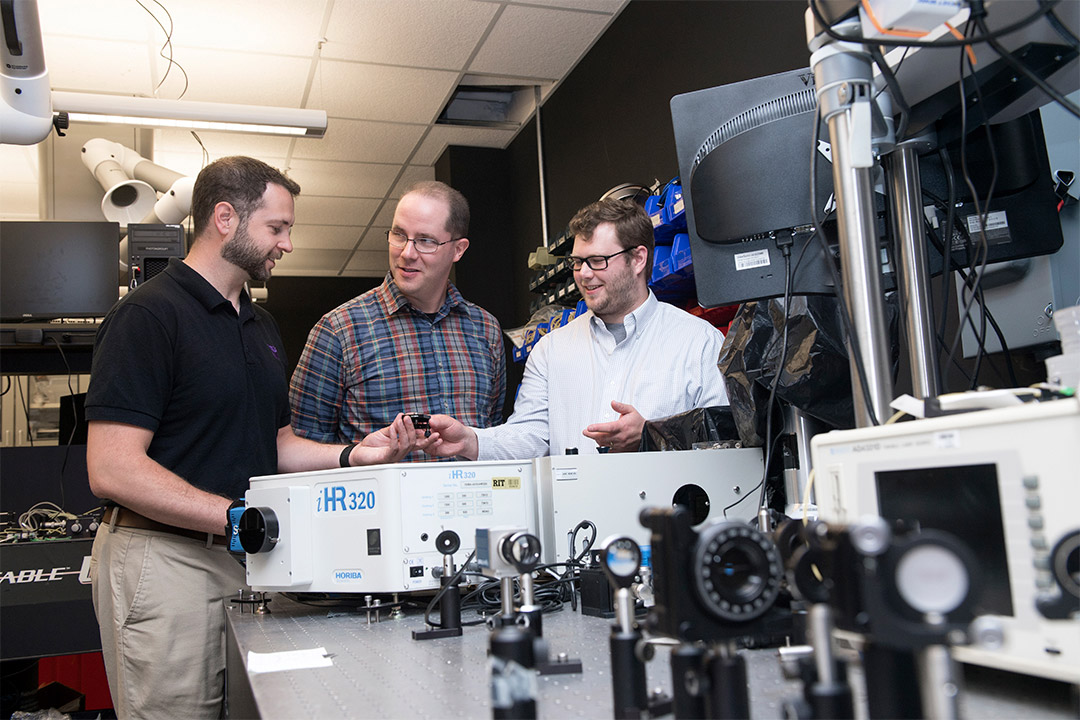

Lobozzo Photonics and Optical Characterization Lab

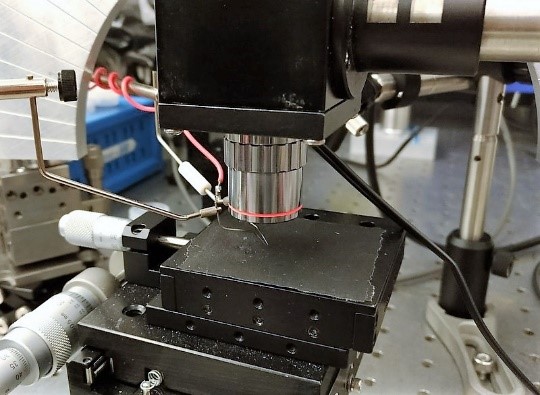

The RIT Integrated Photonics Group conducts research in the Lobozzo Photonics and Optical Characterization lab. Dr. Preble and his team develop high performance nanophotonic devices and systems using complementary metal-oxide-semiconductor compatible materials and processes. Their work enables unique performance and efficiency by leveraging the inherently high bandwidths and low power of photons with the intelligence of electronics. The Lobozzo lab includes a Ti:sapphire laser, optical parametric oscillator, atomic force microscope, ion mill, cryogenic optoelectronic probe station, and telecom test equipment. Other CfD faculty and students use the lab for terahertz measurements and time-resolved photoluminescence.

Integrated Photonics Lab

The Integrated Photonics Group has added space for quantum integrated photonic experiments, called the Integrated Photonics Lab. Researchers use this lab to design and develop scalable quantum computing, communication, and sensing circuits integrated on Silicon Photonic chips. These chips densely integrate photon sources, entanglement circuits, and single-photon detectors onto a phase stable platform. The Air Force Office of Scientific Research (AFOSR) provided funding through the Defense University Research Instrumentation Program for a Photon Spot single-photon detector system. The system has detectors for both short-wave infrared and UV wavelengths. The National Science Foundation, Air Force Research Laboratory, and the Gordon and Betty Moore Foundation fund the laboratories' research projects.

Experimental Cosmology Lab

CfD professor Dr. Michael Zemcov directs the Experimental Cosmology Laboratory. This 375 square foot lab is capable of creating technologies for ground- and space-based applications in experimental astrophysics. The lab has equipment for fabricating and testing physical components and complementary software. Inside the lab are two Oerlikon Leybold Turbolab turbo-molecular pump systems, optical benches, lifting equipment, and tooling and component fabrication equipment. Multiple computers within the lab run algorithms for astrophysics simulations. The lab also includes a millimeter wave spectrometric readout system for transition edge superconducting bolometers, as well as two liquid helium cryostats and an electronic fabrication station. A vibration test system and rapid-prototyping PCB mill adds to the capabilities for cosmology instrumentation and testing in this lab.

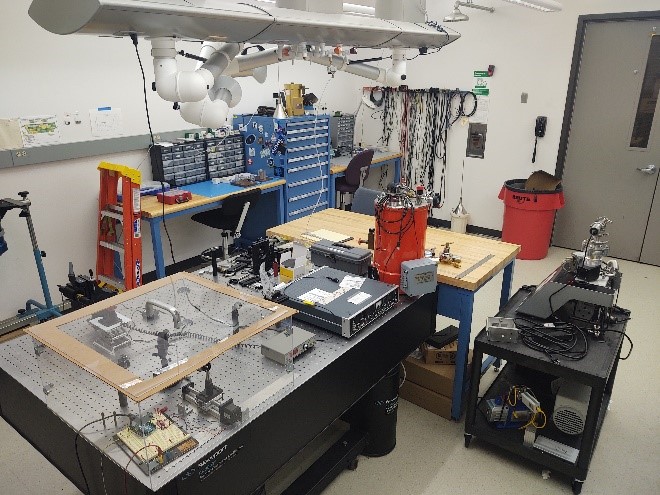

Suborbital Astrophysics Lab

The Suborbital Astrophysics Laboratory provides RIT with capabilities to design, integrate, and calibrate sounding rocket payloads for astrophysical science. It includes clean facilities to allow disassembly and assembly of rocket instruments, optical and electronic development and validation instruments, and cryogenic and vacuum capabilities. In this lab, Dr. Zemcov and his team prepared the CSTARS and CIBER-2 payloads for flight at White Sands Missile Range, NM which launched in spring 2021.

Laboratory for Advanced Instrumentation Research (LAIR)

The Laboratory for Advanced Instrumentation Research (LAIR), led by CfD professor Dr. Zoran Ninkov, is in the Chester F. Carlson Center for Imaging Science, a short distance from the CfD Headquarters. The LAIR develops novel and innovative instruments for gathering data from a wide variety of physical phenomena and trains the next generation of instrument scientists who will occupy positions in government, industry, and academia. It includes hardware and software for developing terahertz (THz) imaging detectors using Si-MOSFET CMOS technology. Over the years, Dr. Ninkov and his team developed a wide variety of instruments at LAIR, including digital radiography systems, liquid crystal filter based imaging systems for airborne (UAV) mine detection, a speckle imaging camera for the WIYN 3.6 meter telescope, a MEMS digital micromirror based multi-object spectrometer, and an X-ray imaging system for laser fusion research. NASA, the NSF, NYSTAR and a variety of corporations such as Exelis, ITT, Kodak, Harris, Moxtek, and Thermo Fisher Scientific, have funded this research.

Expitaxially-Integrated Nanoscale Systems Lab

Dr. Parsian Mohseni leads the Epitaxially-Integrated Nanoscale

Systems Laboratory (EINSL). This lab, part of RIT's Nanopower

Research Laboratory (NPRL), focuses on atomic-level

semiconductor assembly and metalorganic chemical vapor

deposition (MOCVD). The lab develops devices used for

photovoltaics, optoelectronics, and nanoelectronics. Their

research finds real-world applications in solar energy,

solid-state lighting, and lasing. Dr. Mohseni's group is

interested in exploring the fabrication of III-V semiconductor

nanostructures using non-conventional metallic catalysts

composed of carbon-nanotubes and graphene.

Researchers in the EINSL have access to the wide range of

capabilities provided by the NPRL which include a Perkin Elmer

Lamda 900 UV-Vis-NIR optical spectrometer and a metal organic

vapor phase epitaxy (MOVPE). NPRL also has multiple advanced

microscopic imaging systems, including a Nikon Eclipse Digital

Nomarski microscope, Hitachi S-900 High Resolution Near Field

FE-SEM, and Zeiss Digital Microscopic Imaging System.

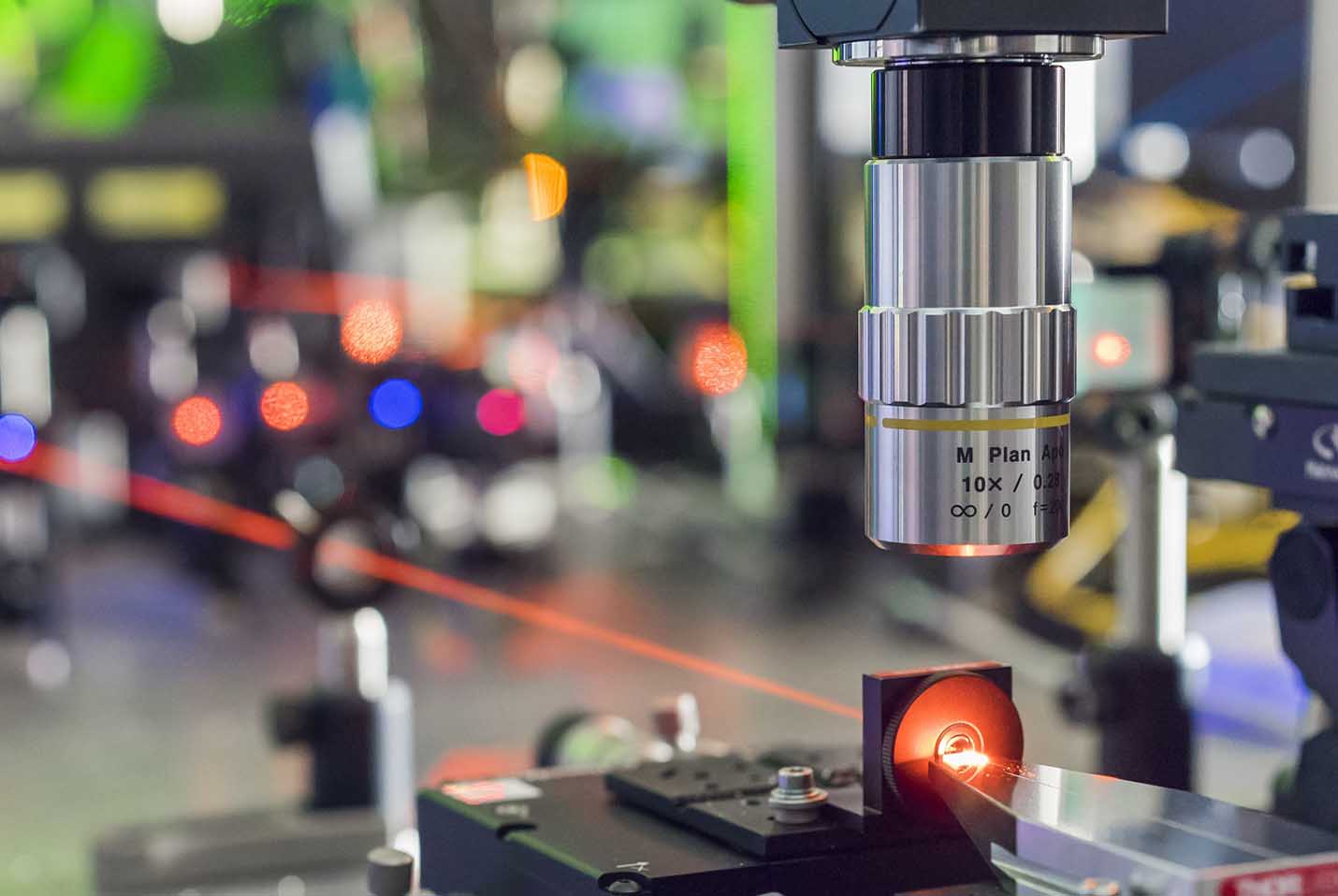

Quantum Imaging and Information Lab

In the new Quantum Imaging and Information laboratory, Assistant Professor Gregory Howland studies how to create, manipulate, and detect quantum mechanical phenomena in the spatial degrees-of-freedom of quantum light. These "Quantum Images" encode large amounts of quantum information of single or entangled photons and serve as a platform for quantum sensing, quantum communication, and quantum computing. Specific research topics range from the applied - such as extreme low-light imaging - to the fundamental - such as quantifying large dimensional quantum entanglement. The 700 square foot laboratory will provide optical benches, laser sources, and single-photon detectors for quantum-optical experiments using bulk, fiber, and integrated optics.

Electrical and Optical Characterization Lab for LED devices

The Electrical and Optical Characterization Lab for LED devices, used by Jing Zhang's research group, makes use of advanced tools and techniques to characterize fabricated devices. These devices include advanced LEDs for applications such as home lighting, display, and quantum computing. The lab includes equipment such as a semiconductor parameter analyzer, electrical probe station, an electroluminescence (EL) measurement setup and a polarization-dependent setup. These tools help describe the power efficiency and optical pattern of the emitted light from these advanced LEDs.

Semiconductor & Microsystems Fabrication Lab (SMFL)

The SMFL is equipped with micro-fabrication and metrology equipment to support research programs in photonic devices, nanomaterials, semiconductor materials and devices, nano-electronics, MEMS devices and sensors. These systems are utilized as part of RIT's role in AIM Photonics, to advance integrated photonics. Using the SMFL's resources, CfD can fabricate detectors with custom process flows and multiple process variations. The lab's flow bench and probe stations offer wafer-level testing, even during the fabrication process, allowing mid-process design changes. The probe station accommodates electrical and circuit analysis of both wafers and packaged parts, including low current and radio frequency (RF) probing.

In addition to fabrication and testing capabilities, the CfD has access to sophisticated simulation software to predict the performance of devices, from fabrication processes to performance of a completed device. Silvaco, Athena, and Atlas are powerful software engines that simulate the effects of processing on device substrates and the electrical characteristics of a fabricated device. Athena simulations can describe all of the processes available in the SMFL, building a physics-based model in 3D space of a device from initial substrate to completed device.

Additional Labs

The CfD uses many other RIT facilities, including the Brinkman Lab, a state-of-the-art facility for precision machining, and the Center for Electronics Manufacturing and Assembly (CEMA), a facility for electronics packaging